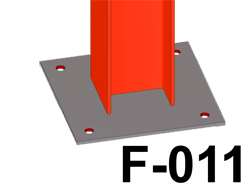

Base Plate

Base plates are used as a support for columns coming off a concrete pad or foundation. To ensure longevity and stability, it is essential to leave a gap of around 20 – 30 mm between the concrete and the steel plate, which can be achieved using shims and wedges. This gap will then need to be filled by packing a dry mixture of concrete, also known as a dry-pack, into the gap.

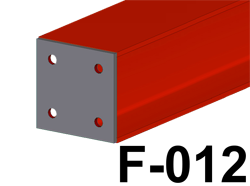

End Plate

An end plate is used to anchor the end of a beam to the wall, and is also part of the ‘End plate connection’.

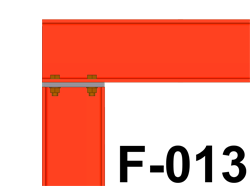

End Plate Connection

This type of connection is used to join a column to a beam or another beam to a flange.

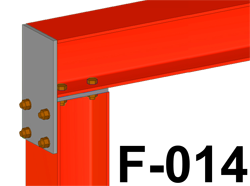

Moment Connection

A moment connection features an overhanging plate that bolts into a column. This type of connection is frequently used when the connection needs to withstand a high ‘moment’, for example if a wall is replaced with a box frame that will need to withstand high wind loads from the sides.

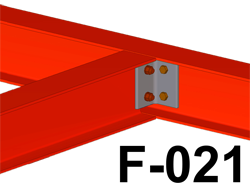

Cleat

A cleat is used to bolt one beam into the side of another beam. Cleats are made from RSA sections (angles), which are then bolted to both beams. In cases where only one side needs bolting, only one cleat will be required, and for some projects it is preferable to weld the cleats to the end of a beam rather than bolting them

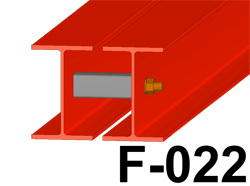

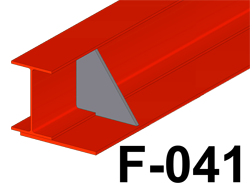

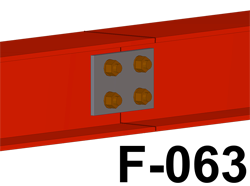

Spacer - Beam

When projects are struggling for height, for instance in basements and lofts, it is often preferable to replace a deep beam with two smaller beams. However, to ensure stability and resistance to buckling, these beams need to be bolted together, and this is where a spacer is used, and is usually welded to one of the beams. The bolts are typically 600 mm apart from each other.

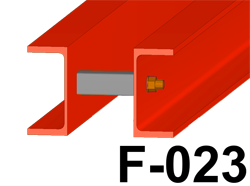

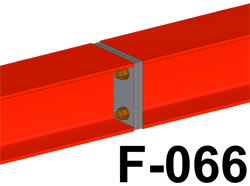

Spacer - PFC

When a cavity wall needs to be supported above an opening, two PFC’s can be bolted together back to back, with a spacer inbetween, in order to give strength to the walls. The gap between the sections matches the width of the cavity, and the spacing between the bolts is 600 mm centre to centre.

Crank 90°

A 90° crank is a typical crank but with two kinks. In a 90° crank the top member will be horizontal and the bottom vertical. Cranked beams are most frequently used to support roof structures, therefore the angle of the middle member needs to follow the pitch of the roof. It is crucial that full penetration welds are used with these connections to ensure the crank will carry the load.

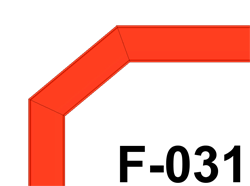

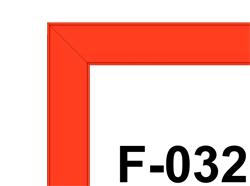

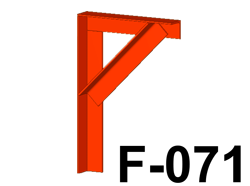

Kink 90°

A 90° kink is a connection of two sections joined by a weld. It is used for brackets, or for when a beam needs to be supported by a column and a bolted connection cannot be used.

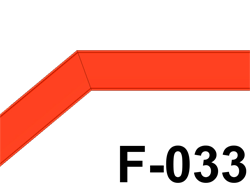

Kink - Angle

With some projects, a single kink that follows the pitch of the roof is adequate for the support required, and the end of the beam is supported without the need of an additional vertical column.

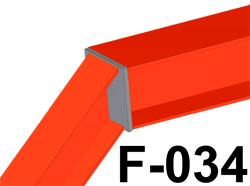

Kink With Plate

This is essentially a ‘kink – angle’, but with an additional plate between the two sections. This type of connection is used when the two pieces being joined are of different sizes.

Gusset

A gusset uses a plate, which is normally triangular, and is used to provide additional stiffness to the structure. It is often used to support the outer edge of a bottom plate welded to a beam.

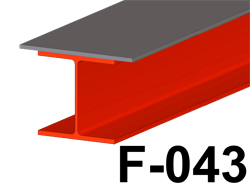

Plate - Bottom

A bottom plate is added to a beam in order to support brickwork or timber joists. The bottom plate is stitch welded to the beam and is often offset to one side so that the brickwork is sufficiently supported.

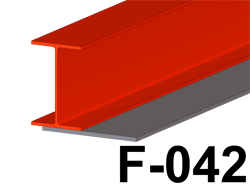

Plate - Top

A top plate is added when the size of the required beam is smaller than the wall it is carrying. An example is a door opening in a cavity wall.

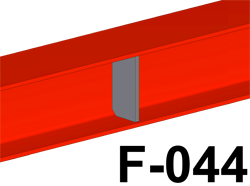

Stiffener

As the name suggests, a stiffener provides additional stability by connecting both flanges and the web. This prevents the web from buckling.

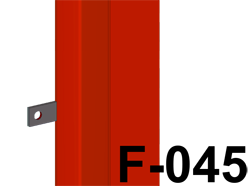

Tab

Tabs are welded to hollow column sections to make it possible to anchor them to walls. In most cases M12 anchors are used every 600 mm and in a staggered formation.

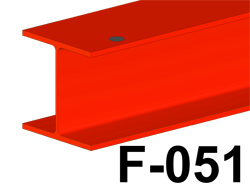

Hole - Flange

Holes are drilled in column flanges, either UC, UB or PFC, in order to anchor them to walls and as an alternative to welding tabs. In most cases M12 anchors are used every 600 mm and in a staggered formation.

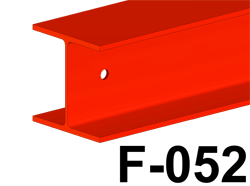

Hole - Web

Holes are drilled in the web of the beam to enable timber joists to be fixed to both sides. Timber joist hangers are then fixed to the beam joists, allowing floor joists to be spanned from it.

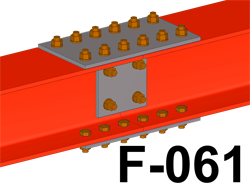

Splice A1

Splices are required when a beam is either too long or too heavy to install safely. When a beam spans two party walls, a splice is also recommended to easily install the beam, with the alternative being temporarily removing a large wall section. As a rule of thumb, the flange plates need to be at least the same thickness as the beam’s flange, and the same rule applies to the web plates.

In some cases HSFG (High Strength Friction Grip) bolts are required, in which case the beam ends and the splice plates must not be primed. These bolts are expensive, so if you are told they are necessary it might be a good idea to request a redesign by your Structural Engineer to enable you to use the normal 8.8 grade bolts.

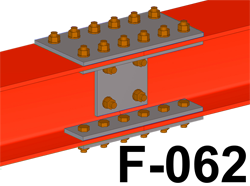

Splice A2

In some cases the structural engineer may request additional inner flange plates for the splice connection.

Splice A3

This type of splice is not a full strength connection and therefore is only used to align two sections. This type of connection needs additional support, either via a column or by a padstone.

Splice B1

When height is limited, regular splices such as A1 and A2 can add as much as 100 mm to the total depth of the beam, therefore are not desirable options. In this case you can consider using a B1 splice, although it is not a full splice and therefore will be unsuitable for some applications.

Gallow Bracket

Gallow brackets have been used to support chimney breasts for many years, however many local authorities no longer allow them to be used. If your planning department advises these are not allowed then you will need to use a full steel beam structure instead.

Structural Steel Connections: Engineering the Backbone of Modern Steel Structures

In the world of structural engineering, while steel beams and columns provide the essential framework, the integrity of any building fundamentally rests upon its Structural Steel Connections. These vital junctions determine how loads are transferred throughout the frame, influencing the structure’s stability, rigidity, and resilience against forces like wind, earthquakes, and gravity. HAS Metal Work Ltd. specializes not only in fabricating precise steel components but, critically, in detailing and producing high-strength Structural Steel Connections that adhere to the strictest British and European standards. The design and fabrication of robust Structural Steel Connections require an intricate blend of material science, structural analysis, and fabrication precision. Any error in detailing or execution can compromise the entire project's structural integrity. This article provides an authoritative deep dive into the types, design principles, fabrication requirements, and importance of Structural Steel Connections in modern construction, highlighting why precision matters for longevity.

Classifying Structural Steel Connections: Types and Functions

Structural Steel Connections are broadly categorized based on the moment resistance they provide and the way forces are intended to be transmitted through the joint. Understanding these classifications is essential for engineers designing a reliable steel structure.

The Distinction Between Simple (Shear) and Moment Connections

Simple connections, often designed using double angle cleats or shear end plates, are intended to transfer only shear forces, assuming negligible rotational restraint. Moment resisting connections, conversely, are designed to transfer significant bending moments, requiring greater rigidity and often involving stiffeners and full penetration welds.

Designing for Structural Steel Connections in Beam-to-Column Joints

Beam-to-column connections are perhaps the most common and critical Structural Steel Connections. Their design dictates the structural system's behavior—whether it acts as a braced frame (relying on shear connections) or a rigid frame (requiring moment connections).

Design Principles and Engineering Standards for Structural Steel Connections

Design must satisfy limit state criteria, ensuring the connections can withstand both ultimate loads (failure prevention) and serviceability loads (preventing excessive deflection or vibration).

Importance of Prequalified Structural Steel Connections

Prequalified connections are those that have been previously tested and standardized, speeding up the design process while ensuring reliable performance. However, bespoke solutions often require specific analysis and verification.

The Mechanics of Bolted vs. Welded Structural Steel Connections

Bolted connections are common due to ease of assembly on site, offering either slip-critical (friction type) or bearing type mechanisms. Welded connections offer greater rigidity and are often preferred for moment frames, but require rigorous quality control during both fabrication and erection, which is vital for safe structural construction.

Fabrication Precision: Translating Design into High-Strength Connections

The transition from engineering drawing to physical component demands impeccable fabrication standards. Precision in cutting, holing, and welding is non-negotiable for reliable Structural Steel Connections.

Ensuring Accurate Hole Alignment for Bolted Connections

In bolted connections, the location and diameter of bolt holes must be highly precise. Poor alignment can result in inefficient load transfer, installation delays, and potential structural issues.

The Criticality of Welding Procedures in Structural Steel Connections

For welded joints, the welding procedure specification (WPS) must be strictly followed. HAS Metal Work employs certified welders and non-destructive testing (NDT) to ensure the weld quality meets the required specification, especially in critical moment connections, reinforcing why precision welding matters.

Specific Structural Steel Connections and Their Applications

Different structural elements necessitate specialized connection designs to handle unique load paths and structural interactions.

Connections for Trusses and Bracing Systems

Truss connections, often relying on gusset plates, require complex detailing to manage the large axial forces in the members. Bracing connections must be designed to resist significant tension and compression forces, crucial for lateral stability.

Detailing Complex Structural Steel Connections for Architectural Features

When steel is exposed for architectural effect, the connections must be both structurally sound and aesthetically refined. This often requires flush joints, hidden bolts, or bespoke cover plates that integrate seamlessly with the design.

Site Erection and Verification of Structural Steel Connections

Even with perfect fabrication, the connection's integrity can be compromised during the installation phase if procedures are not strictly followed. Proper tightening of high-strength bolts using tension control methods is essential for achieving the required slip resistance and bearing capacity in bolted Structural Steel Connections.

Quality Assurance and Inspection on Site

Inspection involves checking bolt tension, ensuring proper fit-up, verifying alignment, and conducting on-site non-destructive testing of site welds. This rigorous process guarantees the connection performs as designed.

Overcoming Misalignment Issues

Despite precision fabrication, minor site discrepancies can occur. Experienced erection teams employ safe, approved methods to correct minor misalignments without compromising the structural integrity of the Structural Steel Connections, relying heavily on professional engineering judgment.

The Future of Structural Steel Connections: Technology and Standards

The industry continues to advance, focusing on smarter, faster, and more resilient connection methods, particularly in response to modern building demands for quick construction and seismic resilience.

The Impact of Automated Fabrication on Connection Precision

Advanced CNC machining and robotic welding enhance the precision of connection details like end plates and splice material, reducing fit-up time and enhancing reliability, contributing to modern architectural excellence.

Designing Structural Steel Connections for Seismic Resistance

In areas requiring seismic design, connections must be detailed to exhibit ductile behavior, allowing the structure to absorb energy during an event without immediate catastrophic failure. This involves specializing in connections that yield predictably.

HAS Metal Work’s Commitment to Robust Structural Steel Connections

HAS Metal Work Ltd. understands that the reliability of the structure hinges on the strength and precision of its Structural Steel Connections. Our integrated service, from design detailing using advanced software to CE-certified fabrication and expert installation, ensures that every connection we deliver is engineered for ultimate performance and longevity. We guarantee high-strength, verified Structural Steel Connections for your most demanding projects.

You must be logged in to post a comment.