What Is Project-Based Metal Fabrication?

Unlike mass production, which focuses on creating identical items in bulk, project-based metal fabrication is centered around custom engineering, precision, and flexibility. Each product is made according to the specific drawings, dimensions, and functional requirements provided by the client or developed collaboratively.

From the initial consultation to the final installation, the entire process is structured around a single, distinct project. This ensures that the final product integrates seamlessly into the broader system or structure it’s designed for.

Why Custom Metal Fabrication Matters

Unique Designs Require Unique Materials

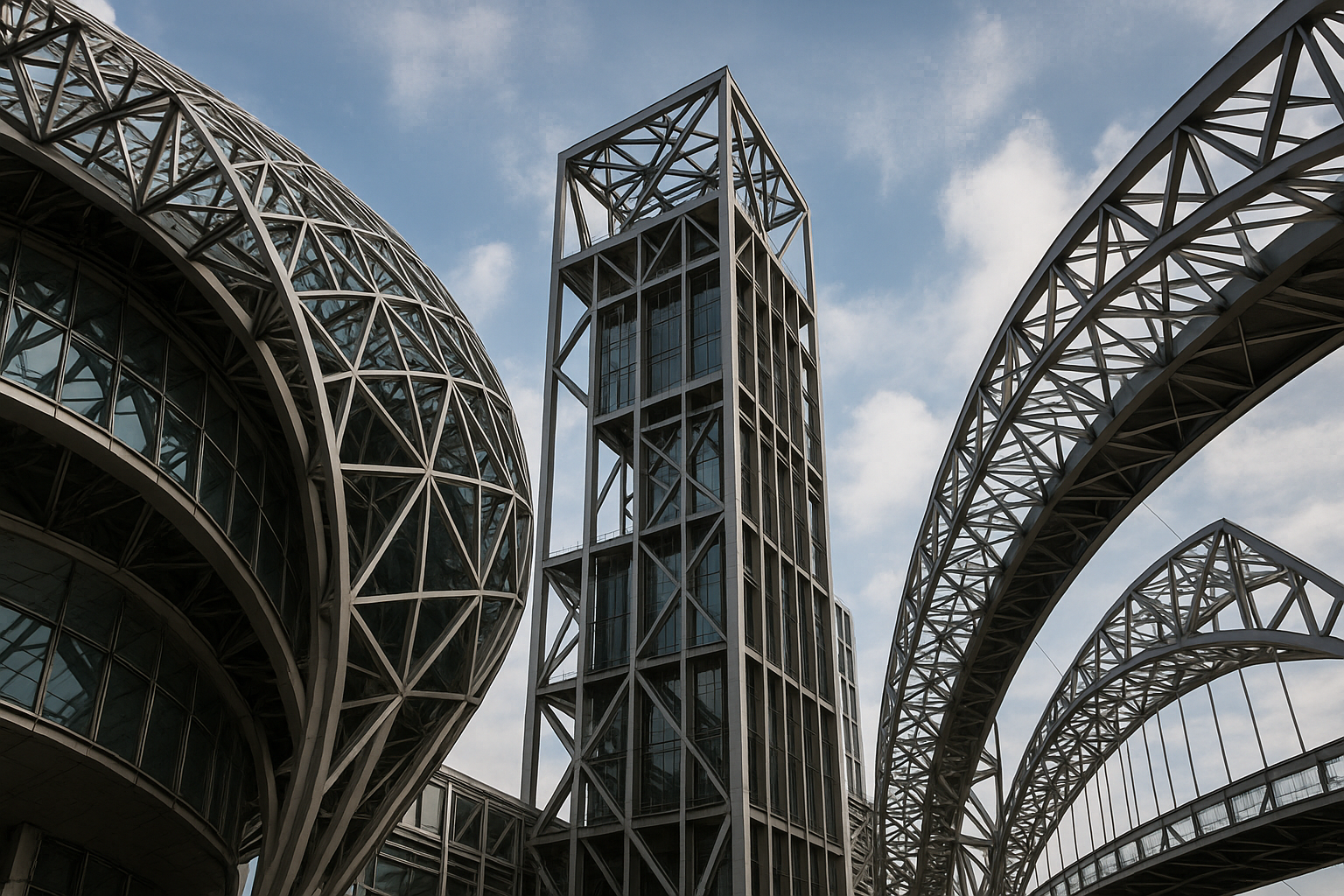

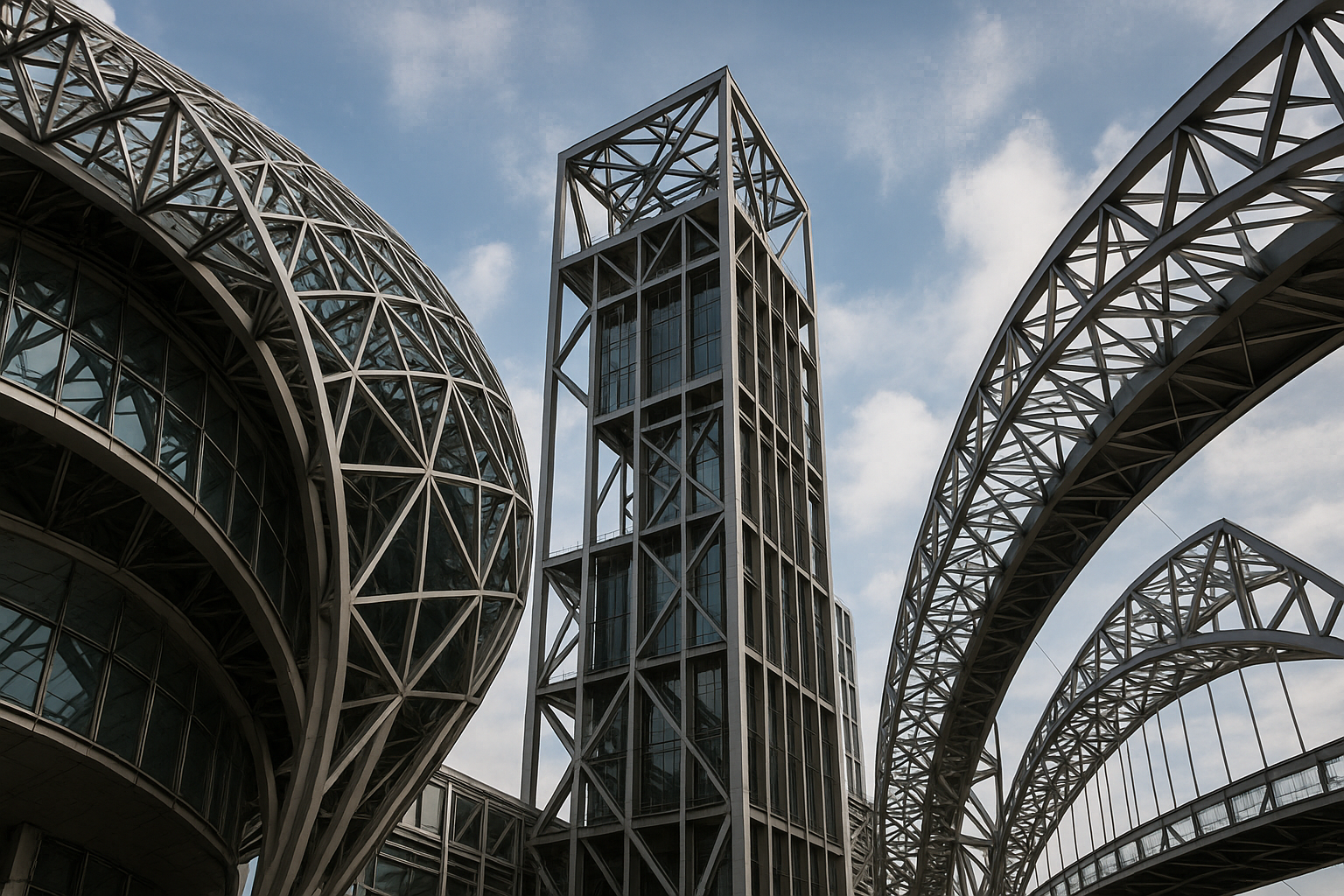

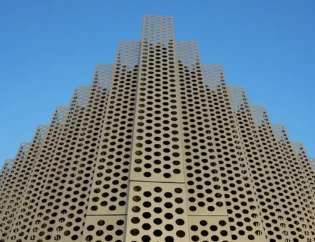

Modern architecture, infrastructure, and industrial installations are becoming increasingly complex. Off-the-shelf components simply cannot accommodate the design demands of today’s advanced systems. Custom fabrication allows clients to break free from standard constraints and explore more innovative, efficient, or space-saving solutions.

Performance Optimization

Custom-fabricated metal components are not just designed to fit—they’re designed to perform. Engineers at Has Metal Works calculate stress points, load capacities, and environmental exposures to ensure every product not only looks right but functions optimally in its environment.

Whether it’s resisting corrosion in coastal climates, supporting heavy machinery, or operating within temperature-controlled facilities, custom solutions outperform standard options.

Seamless Integration

Compatibility is often a hidden cost in industrial projects. A minor mismatch in dimensions or connection types can delay a project for days or even weeks. With project-specific fabrication, all measurements and tolerances are accounted for upfront, ensuring that installation is smooth and error-free.

This results in shorter assembly times, fewer on-site modifications, and lower labor costs overall.

Industries That Benefit from Project-Based Fabrication

While project-based fabrication may sound niche, it serves a wide range of sectors, including:

- Construction – Structural elements, framing systems, roof trusses

- HVAC & Ventilation – Custom ducts, brackets, and mounting plates

- Agriculture – Grain silos, processing equipment, feed systems

- Commercial Architecture – Gates, railings, façade cladding

- Manufacturing & Logistics – Racking systems, platforms, machinery bases

At Has Metal Works, our experience spans across all these industries and more.

Our Process: From Concept to Completion

At Has Metal Works, every project begins with a conversation. We work closely with clients to understand the functional needs, physical constraints, and long-term objectives of their project.

1. Design & Engineering

Our technical team reviews your requirements and translates them into detailed CAD drawings. Where necessary, we offer suggestions to improve durability, functionality, or cost-efficiency.

2. Material Selection

Depending on your project’s environment, we help you choose between stainless steel, carbon steel, galvanized metal, or hybrid solutions.

3. Precision Fabrication

We utilize state-of-the-art machinery for cutting, welding, bending, and surface treatment. Quality checks are conducted at every stage.

4. Delivery & Installation

All parts are packed and delivered according to your schedule. On-site installation can be arranged upon request, ensuring total accountability from start to finish.

Case Study: Custom Ventilation System for a Food Processing Plant

One of our recent projects involved a fully customized stainless steel ventilation system for a large-scale food processing facility. The environment required strict hygiene, temperature control, and corrosion resistance. Off-the-shelf duct systems failed to meet these requirements.

We designed and fabricated each duct section, flange, and bracket to exact tolerances. As a result, the system was installed in record time with zero leaks or compatibility issues—saving our client both time and future maintenance costs.

Why Choose Has Metal Works?

- Experience: Over 8 years of project-based metal manufacturing

- Detail-Oriented: Every weld, hole, and surface is quality-checked

- Client Collaboration: Transparent communication throughout

- All-in-one Solutions: Design, fabricate, and deliver—all in one

We believe that the best outcomes come from fully understanding each client’s vision and bringing it to life through custom metal craftsmanship.

In a world where precision, performance, and personalization matter more than ever, project-based metal fabrication isn’t a luxury—it’s a necessity. At Has Metal Works, we transform raw metal into tailored solutions that empower industries to build better, smarter, and stronger.

Looking for a partner in custom metal fabrication?

Let’s talk. We’re ready to bring your ideas to life with technical expertise and unmatched reliability.

You must be logged in to post a comment.