Introduction: Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work

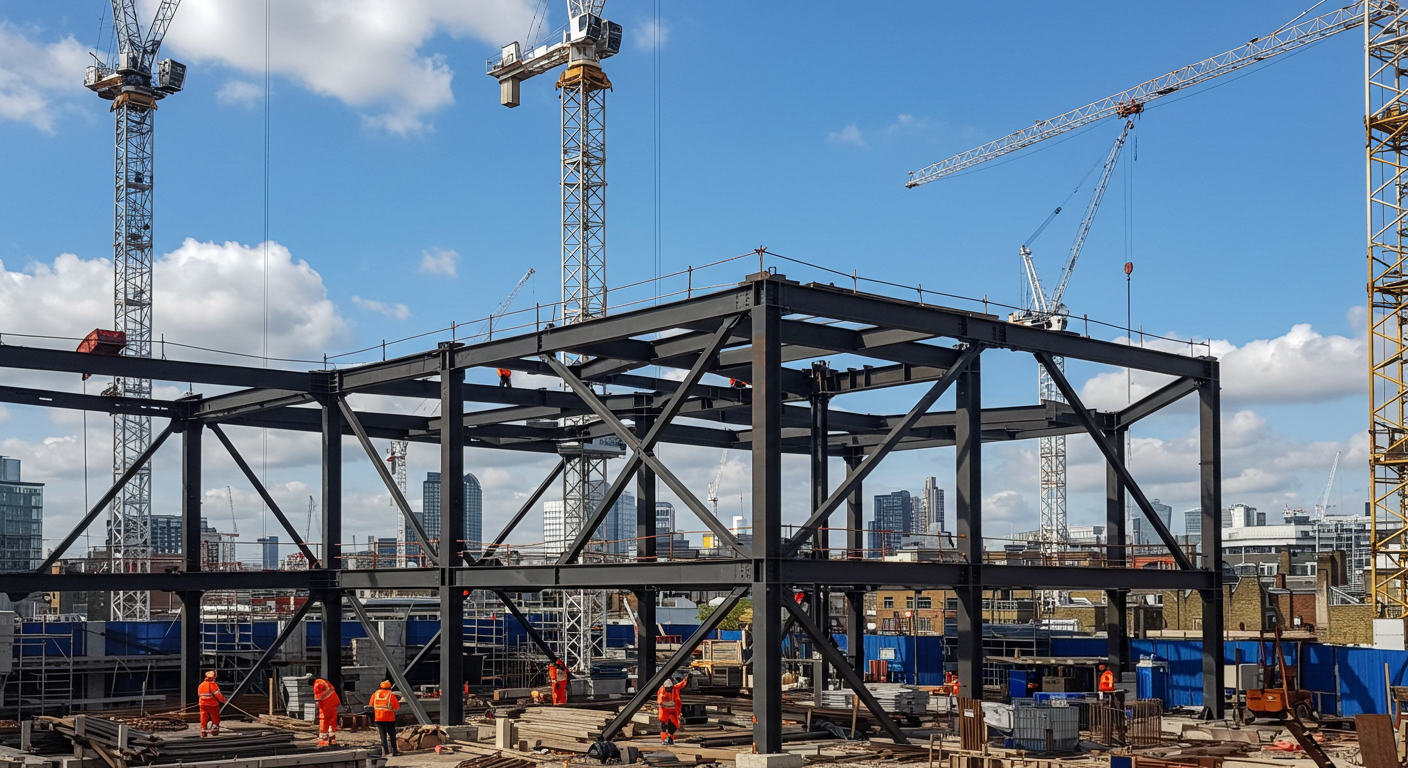

In the dynamic and demanding landscape of London construction, where space is a premium and durability is non-negotiable, the choice of structural material is paramount. For developers, architects, and private clients seeking a combination of strength, design flexibility, and lasting value, the answer lies in bespoke steel structure fabrication. It’s more than just construction; it’s an investment in the future of your property.

At the heart of modern, efficient building practices, steel structure offers unparalleled advantages over traditional materials. While standard, off-the-shelf solutions might suffice for some projects, the unique demands of a city like London—from navigating tight, historical sites to accommodating complex architectural visions—often necessitate a more tailored approach. This is where the true value of bespoke steel structure comes into play. It means engineering a solution specifically designed for the load-bearing requirements, the spatial constraints, and the aesthetic goals of your individual project.

Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work provides a definitive pathway to achieving structural integrity and design excellence. Working across London and the wider English region, Has Metal Work specialises in turning intricate designs into tangible, robust realities. Since 2016, we have been committed to providing a quality Metal Fabrication Service that stands the test of time, weather, and heavy use. Our expertise covers everything from load-bearing steel beams and columns to complex frame assemblies for commercial properties and residential extensions. Choosing bespoke steel is choosing a solution engineered for longevity, minimising future maintenance costs and maximising the lifespan of your investment. It’s a decision that echoes confidence in the stability and permanence of your build. The following comprehensive guide will delve deep into the technical, economic, and practical reasons why bespoke steel structure is the optimal choice for your next London endeavour. Our commitment to precision ensures that every component fits perfectly, speeding up on-site installation and guaranteeing a flawless finish. The structural superiority of steel, coupled with our meticulous fabrication process, makes it the ultimate long-term solution for any ambitious London development.

Technical Details: Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects?

The decision to opt for a bespoke steel structure is fundamentally a technical one, rooted in the superior material properties and engineering flexibility that steel provides. Understanding these technical details is crucial for appreciating the long-term solutions steel offers, especially in challenging urban environments like London.

Material Superiority and Load-Bearing Capacity

Steel possesses one of the highest strength-to-weight ratios of any common construction material. This means a steel beam can bear significantly greater loads than a concrete or timber equivalent of the same size, or it can bear the same load with a much smaller, lighter profile. This is an enormous advantage in London, where foundation costs are high and architects often seek to maximise internal space.

Yield Strength and Durability

The yield strength of structural steel is the point at which the material begins to deform permanently. Modern structural steel exhibits a very high yield strength, ensuring that the finished structure can withstand extreme static and dynamic loads without permanent damage. This resilience directly translates into durability. Furthermore, when correctly fabricated and installed, steel structures are inherently resistant to seismic activity and wind loading—critical factors for tall buildings and structures situated near busy transport links. The precision fabrication offered by Has Metal Work ensures that all components meet stringent British and European standards for material quality and weld integrity.

Precision Fabrication and On-Site Efficiency

Bespoke fabrication is not just about custom sizing; it’s about achieving millimetre precision in every component. Unlike concrete pouring or traditional timber framing, which are heavily reliant on on-site conditions and manual labour for dimensional accuracy, steel members are cut, drilled, and welded in a controlled factory environment.

The Advantage of Off-Site Manufacturing

Manufacturing the structure off-site at a facility like Has Metal Work significantly improves quality control, reduces material waste, and drastically speeds up the project timeline. When the components arrive on the London construction site, they are pre-fitted with connection points, ready for swift assembly. This ‘kit-of-parts’ approach minimises on-site disruption—a major benefit when working in congested areas—and reduces the duration of noisy, messy construction phases. The accuracy of bespoke fabrication eliminates time-consuming adjustments and errors often encountered during traditional building, ensuring that the structure goes up correctly the first time. This level of technical planning and execution is essential for complex steel structures such as multi-story extensions or intricate roofing supports.

Design Flexibility and Architectural Freedom

Steel’s inherent strength allows for greater spans without intermediate columns, providing architects with unparalleled freedom in internal design. This is particularly valuable for commercial and retail spaces that require large, unobstructed floor areas.

Creating Complex Geometries and Open Spaces

For projects requiring large cantilevers, open-plan office spaces, or complex roof geometries—common features in contemporary London architecture—steel structure is the only viable choice. Bespoke steel components can be engineered to support these features while maintaining a visually light and minimal profile. Our capacity to work with advanced 3D modelling and CAD systems allows us to fabricate unique shapes and connections, ensuring that the aesthetic vision is fully realised without compromising structural safety. This design freedom is one of the core arguments for choosing Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work for unique architectural challenges.

Sustainability and Adaptability

Modern construction increasingly demands sustainable practices. Steel is one of the most recycled materials globally, making it an environmentally responsible choice.

Recyclability and Future Adaptation

Structural steel is almost 100% recyclable, and its quality is not degraded in the process. This contributes significantly to a project’s long-term sustainability credentials. Furthermore, a bespoke steel structure is inherently adaptable. Unlike rigid concrete, steel frames can be easily modified, extended, or even disassembled and reassembled elsewhere. This adaptability is a crucial element of a long-term solution, allowing the structure to evolve with the changing needs of the business or property owner over decades, preventing obsolescence and costly future demolitions.

Key Features: Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects?

Choosing a bespoke steel structure from a specialist like Has Metal Work goes beyond simply ordering materials; it includes a suite of essential features that collectively guarantee a superior and long-term solution for your London project.

Custom-Engineered Load Distribution

The single most important feature of a bespoke service is the custom engineering process. We calculate precise load paths and stresses specific to your building’s location, intended use, and architectural configuration. This results in an optimally designed frame where every beam and column is sized perfectly—no unnecessary bulk, no compromise on strength.

Advanced Corrosion and Fire Protection

Structural steel must be protected to ensure its durability and safety. Our bespoke service includes the application of specialised coatings:

Fire-Resistant Coatings (Intumescent Paint)

Steel, while non-combustible, can lose its structural integrity at very high temperatures. We apply intumescent coatings which expand when exposed to heat, insulating the steel and buying critical time for evacuation and firefighting. This is a vital safety feature for any commercial or residential building in the densely populated London area.

Anti-Corrosion Treatments (Galvanisation and Primers)

For external or high-moisture applications, we offer options such as hot-dip galvanisation or specialized epoxy primers. These treatments create a protective barrier against the elements, preventing rust and ensuring the steel structure retains its strength and appearance for decades, even in the harsh, humid UK climate.

Integrated Connection Detailing

A critical feature of our bespoke service is the precise detailing of connection points (flanges, bolt holes, gusset plates). These are pre-fabricated to exacting standards in the workshop, which eliminates on-site drilling and cutting. This integration ensures that the structure bolts together seamlessly, accelerating installation and reinforcing the overall structural integrity of the frame. This precision is a hallmark of Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work.

Full Traceability and Certification

Every fabricated component comes with complete material traceability and certification. This ensures that the steel used meets British Standards and provides clients, engineers, and building control officers with full assurance of the material quality and compliance. This level of documentation is an indispensable feature for any major construction project in the UK.

Application Areas: Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects?

The versatility of bespoke steel structure allows it to be the preferred material across a vast spectrum of construction and renovation projects in London and throughout the UK. Its application is limited only by architectural imagination.

Commercial and Industrial Structures

Warehouses and Logistics Hubs

Bespoke steel is the ideal choice for large-span industrial buildings like warehouses and distribution centres. Steel frames allow for vast, column-free interiors, which are essential for accommodating machinery, racking systems, and efficient vehicle movement. Has Metal Work provides the heavy-duty structural integrity necessary for these environments.

Office Blocks and Mixed-Use Developments

In London, modern office towers and mixed-use buildings rely heavily on steel. It facilitates rapid construction, allows for the large, open-plan floor plates desired by modern tenants, and simplifies the integration of sophisticated building services (HVAC, data). The speed of steel installation is a critical factor in urban areas where minimising disruption and maximising return-on-investment timelines are key priorities.

Residential Applications

Loft Conversions and Rear Extensions

Even small-scale residential projects benefit from bespoke steel. For loft conversions requiring the removal of internal walls or the creation of large rear extensions with bi-folding doors, steel provides the necessary support with the slimmest possible profile, maximising headroom and natural light. Our service ensures the beams are cut precisely to fit within existing structures.

Basement Construction

Building basements in London often involves complex structural engineering to support the existing house and the surrounding ground. Bespoke steel shoring and framework are essential for ensuring the stability during the excavation process and for creating the permanent, robust structure of the new subterranean space.

Infrastructure and Specialist Projects

Bridges, Walkways, and Canopies

Steel is inherently suited for infrastructure elements like pedestrian walkways, small bridges, and large external canopies. Its strength allows for necessary spans, and its durability withstands heavy use and environmental exposure. The bespoke approach ensures that public access structures adhere to the strictest safety standards and seamlessly integrate with the existing urban environment.

Specialist Machinery Bases

In industrial settings, bespoke steel platforms and bases are often required to support heavy, vibrating machinery. These must be custom-designed to absorb specific dynamic loads. This is a prime example of where only a long-term solution involving precision-engineered steel will suffice.

Case Studies: Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work

In construction, theory must always meet practical application. The following case studies illustrate the tangible benefits of choosing Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work across diverse projects in the London area.

Case Study 1: The Multi-Story Residential Infill Project, Islington

An ambitious residential developer needed to construct a complex four-story apartment block on a narrow, challenging infill site in Islington. The site required deep excavation and precise alignment with neighbouring properties.

Challenge: Speed and Spatial Constraints

The primary challenge was the extremely tight access and the need to complete the structural frame rapidly to minimise disruption in the busy urban street. Traditional construction would have taken months longer and required excessive on-site storage.

HAS Metal Work Solution: Phased Just-in-Time Delivery

Has Metal Work fabricated the entire steel frame off-site, including complex moment-resisting connections for seismic stability. We implemented a Just-in-Time (JIT) delivery schedule, delivering only the components required for each floor section as they were needed. This approach allowed the frame to be erected in weeks, not months, drastically shortening the overall build time and demonstrating the efficiency of a bespoke steel structure solution.

Case Study 2: Open-Plan Commercial Office Conversion, Shoreditch

A former 1960s industrial building in Shoreditch was being converted into a modern, open-plan technology hub. The client demanded vast, column-free spaces on all floors to allow for maximum flexibility in office layout.

Challenge: Removing Load-Bearing Walls and Maximising Spans

The existing building had numerous internal load-bearing walls that needed removal to achieve the open-plan design. This required the installation of extremely long, heavy-duty primary beams to carry the load of the floors above.

HAS Metal Work Solution: Bespoke High-Span Steel Beams

We engineered and fabricated bespoke high-span steel beams that were craned into position. Crucially, we designed the connections to allow the new steel structure to interface seamlessly with the older, less-precise concrete structure of the original building. This precision engineering was key to providing the desired aesthetic freedom while ensuring superior structural integrity and proving that a custom-engineered frame is the definitive long-term solution for major commercial retrofits.

Case Study 3: Custom Glass Atrium and Walkway Structure, Canary Wharf

A corporate client in the Canary Wharf district required a striking, contemporary glass atrium and elevated walkway connecting two existing office towers. The structure needed to be visually light but structurally robust against high winds.

Challenge: Aesthetic Lightness and High Wind Resistance

The design called for a minimalist look with very thin steel profiles to maximise the glass area, while simultaneously needing to withstand significant wind shear typical of the docklands area.

HAS Metal Work Solution: Finite Element Analysis and Precision Hollow Sections

Using advanced engineering analysis, Has Metal Work fabricated the structure using high-strength, precision-cut hollow structural sections (HSS). The bespoke connections were nearly invisible, yet incredibly strong. The result was a stunning, airy structure that met all load-bearing and wind-resistance requirements. This exemplified the superior design flexibility inherent in choosing Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work for architectural statements.

Case Study 4: Residential Extension with Extensive Cantilevers, Richmond

A high-end residential project in Richmond required a large rear extension featuring a dramatic cantilevered corner—a popular modern design element to create an uninterrupted connection between the home and the garden.

Challenge: Structural Support for a Floating Corner

The primary challenge was engineering a hidden steel structure capable of supporting the dead and live loads of the roof and walls above the unsupported, “floating” corner of the extension.

HAS Metal Work Solution: Integrated Concealed Framework

We fabricated a fully concealed steel frame that transferred the cantilevered load back to the main house structure and foundation. The steel was installed with such precision that it was completely masked within the walls and ceiling, allowing the architect’s vision of an open, floating corner to be realised without any visible structural supports. This subtle integration highlights the power of bespoke fabrication in achieving complex architectural goals.

Frequently Asked Questions (FAQ): Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects?

Here we address common queries regarding the specification, fabrication, and installation of bespoke steel structures in London projects.

Is Bespoke Steel Structure More Expensive Than Standard Solutions?

Answer: While the initial fabrication cost may be slightly higher than generic, stock steel sizes, the overall project cost-effectiveness is superior. Bespoke steel structure is designed to minimise material waste (as it’s cut exactly to size), dramatically speeds up on-site installation (reducing expensive labour time), and is engineered for optimal performance, preventing costly modifications later. Furthermore, its superior long-term solution durability and lower maintenance requirements make it a better financial investment over the lifespan of the building.

How Long Does the Bespoke Fabrication Process Take at Has Metal Work?

Answer: The timeline for the fabrication of a bespoke steel structure depends heavily on the complexity and size of the project. Once the final engineering drawings are approved, the manufacturing process typically takes between 2 to 6 weeks. Our controlled workshop environment ensures consistent progress. We then work closely with your site team to coordinate a streamlined delivery and installation schedule to minimise site time, which is particularly valuable in congested London locations.

What Kind of Structural Maintenance Does a Bespoke Steel Frame Require?

Answer: A properly treated and protected bespoke steel structure requires minimal maintenance. If the steel is internal and correctly sealed, virtually no maintenance is needed. For external or exposed elements that have been galvanised or coated with high-quality industrial paint by Has Metal Work, periodic inspections (typically every 10-20 years) may be necessary to check for any damage to the protective coating. The durability inherent in Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work means far less long-term maintenance hassle than materials prone to warping or rot.

Can Has Metal Work Assist with the Design and Engineering Phase?

Answer: Absolutely. While we primarily work from your architect’s and structural engineer’s plans, our in-house team possesses extensive experience in steel construction methods. We frequently collaborate during the design phase (value engineering) to advise on the most efficient and cost-effective ways to fabricate the required steel structure. This partnership ensures that the design is not only structurally sound but also optimised for manufacture and installation, guaranteeing a smoother project from inception to completion.

What are the Environmental Benefits of Using Structural Steel?

Answer: Structural steel is one of the most environmentally friendly construction materials available. It has a high percentage of recycled content and is nearly 100% recyclable at the end of the building’s life without losing its quality. This circular nature significantly reduces the project’s carbon footprint compared to materials like concrete, which are high-emission. Choosing a bespoke steel structure is a responsible choice for sustainable, long-term solutions in modern UK construction.

Is Bespoke Steel Suitable for Historical or Listed Buildings in London?

Answer: Yes, in many cases, bespoke steel is the best solution for renovations or extensions to historical or listed buildings. Because of its high strength-to-weight ratio, steel can provide necessary structural support with minimal intrusion or impact on the existing delicate historic fabric. The precision of bespoke fabrication ensures that new structures fit perfectly within the often-irregular dimensions of older buildings, preserving the character while upgrading the structure for modern use.

Choosing Long-Term Solutions: Why Choose Bespoke Steel Structure for Your London Projects? | Has Metal Work is a definitive statement of intent regarding the quality and durability of your investment. From the bustling construction sites of Shoreditch to the quiet residential streets of Richmond, the superior technical specifications, high degree of customisation, and inherent material strength of bespoke steel structure offer unparalleled benefits.

Has Metal Work, serving London and England since 2016, is committed to translating complex architectural visions into flawless structural reality. By embracing off-site precision fabrication and implementing advanced protective measures like fire-resistant coatings and galvanisation, we ensure that your build is not just for today, but for generations to come. For any client requiring structural integrity, design flexibility, and a streamlined construction process, a bespoke steel solution is the only logical choice. Ready to secure your project’s future with the ultimate structural material?

You must be logged in to post a comment.