At Has Metal Work, steel isn’t just a material it’s the foundation of bespoke, enduring craftsmanship. Our steel fabrication projects exemplify our commitment to precision, innovation, and long-term structural integrity. From architectural components to industrial frameworks, we combine engineering expertise with design finesse to deliver results that elevate every space they’re built for.

Every project begins with a tailored approach: we listen, assess, and innovate based on your vision and our technical insights. Whether it's a decorative railing system, structural beamwork, or bespoke commercial steel solutions, our team ensures durability, safety, and sleek aesthetics in every cut, weld, and finish. Let your next project stand on a steel foundation forged by experience.

Contact Has Metal Work today to explore how our steel fabrication can bring your ideas to life stronger, smarter, and more refined than ever.

Featured Projects

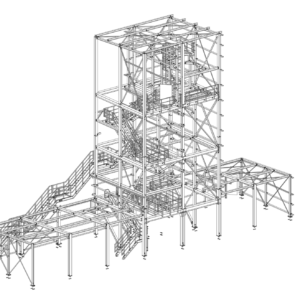

HHCR Plant in Castrop - Rauxel - Dortmund, Germany

Project Name: HHCR Plant in Castrop-Rauxel

Client: Thyssenkrupp Industrial Solutions AG

Location: Dortmund, Germany

Steel Weight: 1,000 tons

Project Description:

The HHCR Plant project in Dortmund represents a significant achievement in industrial steel construction, tailored for the complex operations of a high-capacity chemical processing facility. The project involved the fabrication and assembly of roughly 1,000 tons of structural steel, including intricate truss systems, beams, and columns.

Structural Highlights:

Large-scale framework: The structure spans a vast area, supporting multiple process units and equipment.

Precision engineering: Advanced steel-cutting and welding techniques ensured seamless integration of all components.

Robust design: Optimized for durability, safety, and operational efficiency.

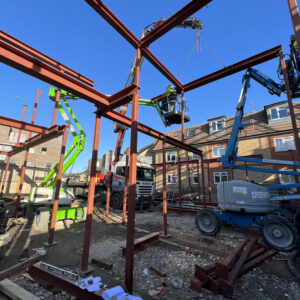

Bedlam Mews - Office Building

Project Name: Bedlam Mews

Client: CMT Construction

Location: Bedlam Mews, London

Steel Weight: 20 Tons

Project Description:

This project involved the fabrication of a steel structure for a new office building located at Bedlam Mews. The structure was designed and executed for CMT Construction, ensuring strength and stability with a focus on precision in fabrication and quality materials.

Key Features:

-

Material Used: High-strength Universal Columns and Beams.

-

Design Details: The structure includes multiple steel frames with cross-bracing to provide optimal support and resistance against lateral forces.

-

Precision Manufacturing: Components were fabricated to strict specifications for seamless on-site assembly.

-

Bolt and Weld Connections: Bolts and welds used in the connections adhere to the highest standards, with bolts being a minimum of 4.4 or 8.8 grade for structural integrity, and weld thickness starting from 6mm.

Trafalgar Rd - New Build - Residential

Project Name: Trafalgar Rd.

Client: CMT Construction

Location: Trafalgar Road, London

Steel Weight: 65 tons

Key Features:

-

Steel Components: Utilized high-strength steel sections, including Universal Beams and Columns, forming the structural framework. The following steel members were used for each floor.

-

Steel Columns: Approximately 12–16 primary columns for vertical support.

-

Steel Beams: 20–30 beams, forming the horizontal framework.

-

Cross Bracing: 3–5 diagonal braces for added lateral stability.

-

Protective Coatings: Advanced anti-corrosion treatments for enhanced durability and weather resistance.

-

Bolt & Welding Specifications: Grade 4.4 and 8.8 bolts were used for all connections, with a minimum weld thickness of 6 mm in required sections.

Tamworth Yard - New Build - Residential

Project Name: Tamworth Yard

Client: CMT Construction

Location: Tamworth Yard

Steel Weight: 60 tons – 2 Buildings

Project Description:

The Tamworth Yard Residential Project, developed for CMT Construction, involved the design, fabrication, and installation of steel structures for two new build residential buildings, each weighing 30 tons for a total of 60 tons. The project was completed within 45 days, utilizing a mix of SHS, UC, UB, and PFC steel sections for enhanced strength and stability.

Key Features:

- Material Used: High-strength steel sections including SHS, UC, UB, and PFC were chosen to ensure robust structural support.

- Galvanised Elements: Some steel elements were galvanised for enhanced corrosion resistance, ensuring long-lasting durability.

- Lintel Fabrication: Specialized plate bending techniques were used to create custom lintels, designed to meet the architectural needs of the residential buildings.

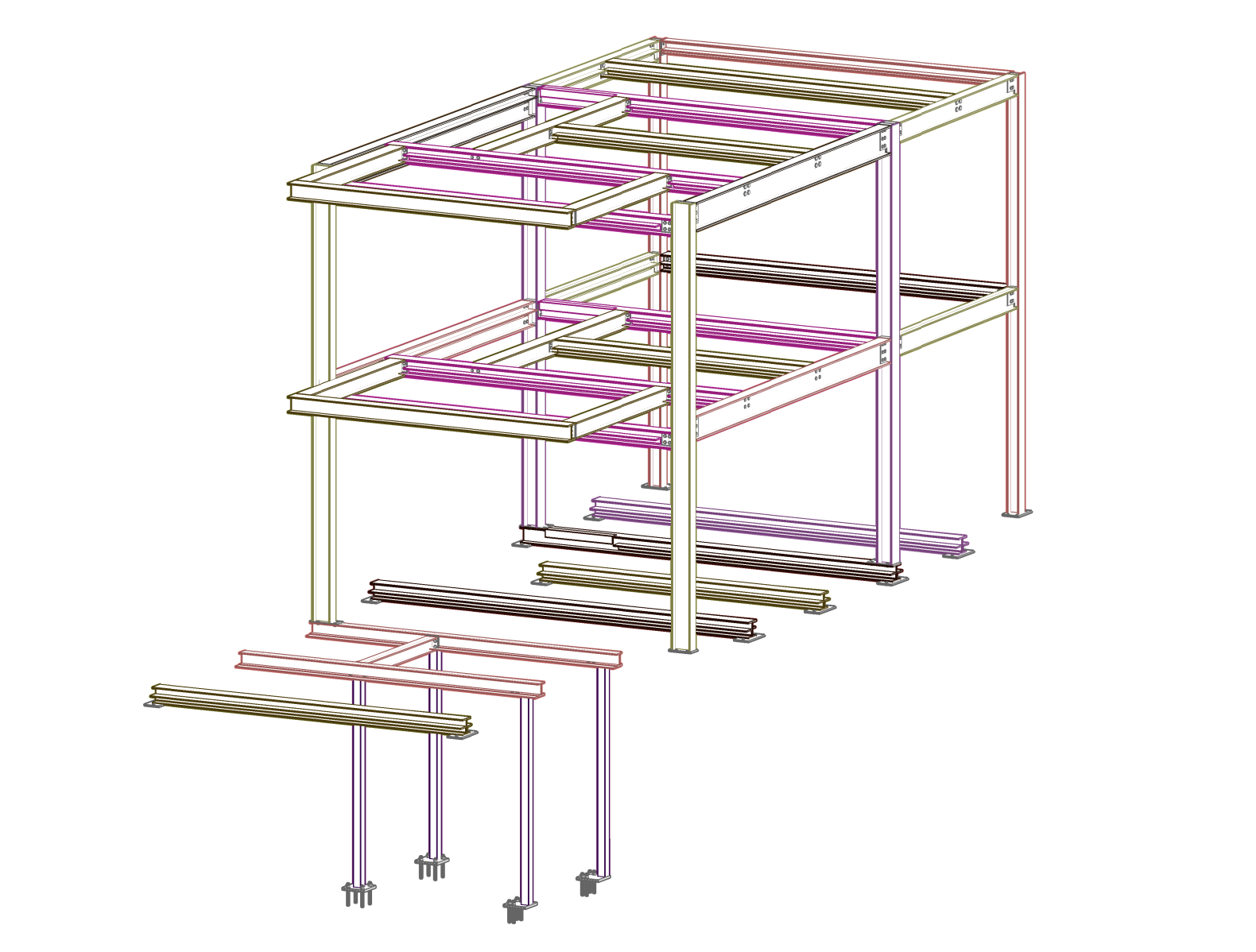

Steel Fabrication Factory - Harlow

Project Name: Dewar House Facility

Client: Country Fashion Ltd.

Location: Cental Rd. Harlow

Steel Weight: 155 tons

Project Description:

This project highlights our ability to deliver complex and high-quality steel structure solutions. Completed for Country Fashion Ltd., this project involved the fabrication and installation of a 155-ton steel structure over the course of 80 days, showcasing our commitment to meeting tight deadlines while maintaining exceptional standards of workmanship.

Structural Design & Components:

The project made use of Circular Hollow Sections (CHS), Rectangular Hollow Sections (RHS), and Universal Columns (UC), all of which were fabricated in our workshop before being transported to the site for installation. These components formed the core framework of the structure, providing robust support and stability.

Key Structural Features:

Base Plates & Moment Connections: These crucial components ensured proper load distribution and stability of the structure.

Custom Fabricated Components: Each steel element was carefully designed to meet the building’s specific functional and design requirements.

Ridge Rd Haringey - New Build Residential

Project Name: Ridge Rd. Haringey

Client: CPI Cakir Property Investment Ltd.

Location: Ridge Rd, Haringey, London

Steel Weight: 10 tons

Project Description:

Located in Haringey, London, this New Build Residential project consisted of a 3-story steel structure. The entire framework, including the primary load-bearing elements and beams, was fabricated using UC steel sections. These sections were chosen for their ability to support large spans while maintaining aesthetic integrity, eliminating the need for visible columns that could obstruct views or landscapes.

Key Features:

- Steel Types Used: UC (Universal Column), PFC (Parallel Flange Channel)

- Time to Complete: 1 week fabrication, 2–3 days installation

- Efficiency: Quick turnaround for high-quality results

- Aesthetic: No visible columns obstructing views

The use of high-strength UC beams allowed for wide open spaces and the building was constructed without compromising on structural strength or appearance. The project was completed efficiently, with all major steel components being installed within 10 days.

You must be logged in to post a comment.